-

Mirror

MirrorA beam splitter is a lens that divides a beam of light into reflected light and transmitted light, can also separate the two wavelengths of light, such as , the fundamental wave and Double frequency wave of the frequency-doubled laser are separated.It can also be at a certain wavelength (such as 1064nm) or Separation of s-polarized light and p-polarized light in a certain band (such as 450-650nm).

-

45 degree beam splitte

45 degree beam splitte45 degree beam splitter

Base material: Fused quartz, K9 glass

Face shape::<λ/10 @ 632.8nm Degree of finish:40-20 Chamfer:0.5mm, 45° Coating:Electron beam deposition multilayer dielectric coating Angle of incidence:0°,45° Clear aperture :> 85% diameter

laser-damaged threshold ::>5J/cm2(1.06μm,1ns) -

Dual color beam splitter

Dual color beam splitterBase material: Fused quartz, K9 glass

Face shape::<λ/10 @ 632.8nm Degree of finish:40-20 Chamfer:0.5mm, 45° Coating:Electron beam deposition multilayer dielectric coating Angle of incidence:0°,45° Clear aperture :> 85% diameter

laser-damaged threshold ::>5J/cm2(1.06μm,1ns) -

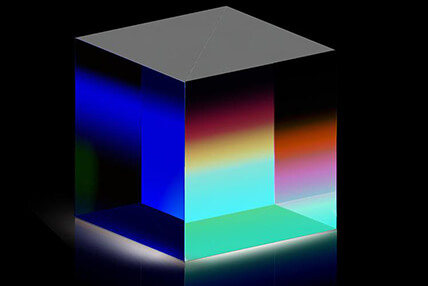

polarization splitting prism

polarization splitting prismpolarization splitting prism

Base material: Fused quartz, K9 glass

Face shape::<λ/10 @ 632.8nm Degree of finish:40-20 Chamfer:0.5mm, 45° Coating:Electron beam deposition multilayer dielectric coating Angle of incidence:0°±2° Clear aperture :> 85% diameter

Polarization transmittance: Tp≥98%; Ts≤0.2%

extinction ratio: Tp:Ts>500:1

Antireflection film on each passing surface:R<0.25% -

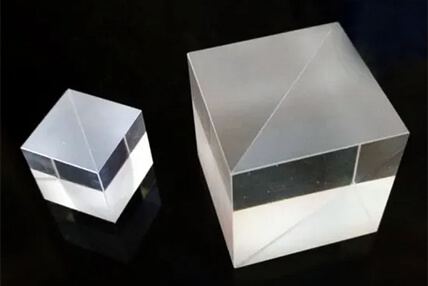

Polarizing splitter

Polarizing splitterPolarizing splitter

Base material: fused silica, K9 glass

Surface type: <λ / 10 @ 632.8nm Finish: 40-20 Chamfer: 0.5mm, 45 ° Coating: Multi-layer dielectric film deposited by electron beam Incidence angle: 56.5 ° ± 3 ° Clear aperture:> 85% diameter

Polarization transmittance: Tp≥96%; Ts≤1%

Extinction ratio: p: Ts> 100: 1

Band range: visible area, near infrared -

IR/DLC

IR/DLCIR coating refers to a coating in the infrared region of 2.5 μm (2500 nm) to 16 μm. There is a big difference between IR coating and near infrared coating in the choice of materials and manufacturing technology. They are mainly used in industrial and medical laser equipment, such as CO2 laser, Er:YAG laser, CO, HF laser.

The DLC coating window is a technique for forming plasma in a high vacuum state and coating the product surface with carbon as the main component of diamond, which is manufactured using PVD or CVD equipment. The DLC coating serves as a window to increase the transmittance in the infrared region, and is applied to products that require high durability and hardness on the surface exposed to the outside. By using a dielectric on one side of the DLC coating, it can show higher transmittance and continue to be a high-quality product for imaging applications.

- Crystal Material

- Lanthanum tribromide LaBr3

- Calcium fluoride (CaF2)

- Barium fluoride(BaF2)

- Magnesium fluoride (MgF2)

- Lithium fluoride(LiF)

- Silicon material(Si)

- Germanium material(Ge)

- NaI:TI

- Lithium Niobate

- Zinc Selenide(ZnSe)

- Zinc Sulfide(ZnS)

- Sapphire

- Quartz

- Laser Lenses

- Laser output Coupler

- Laser Protection Window

- Beam Combine

- Laser scanning mirror

- Laser Mirror

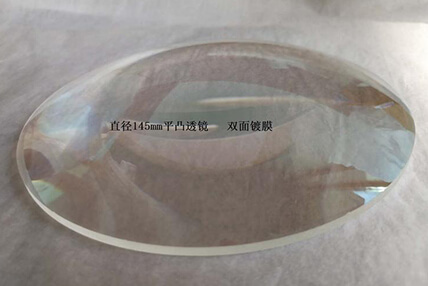

- Focusing Lens

- Laser Window