Magnesium fluoride(MgF2) 121nm Material

The extreme ultraviolet magnesium fluoride material must be high purity material, and the crystal growth process must be controlled by atmosphere to obtain higher transmittance, and because of the complexity of the photoion welding process, the crystal orientation, microstructure, lens processing and annealing requirements are extremely demanding. We are currently the world’s leading supplier of this product, specializing not only in materials but also in applications.

Applications :

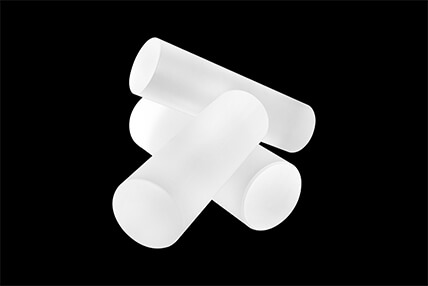

D6*1 magnesium fluoride, D8*1 magnesium fluoride, D12.7*1 magnesium fluoride, D30*2 magnesium fluoride

Product Advantage :

Supply capacity: D0.25-1 inch * thickness 0.3-1.1 mm lens, over 1000K per year

Processing capacity: 40-20, 1/4L.

Product capacity: 60%@121NM, low stress, high transmission

Orientation capability: C-CUT, A-cut

Product Parameters :

1. Do I need to provide actual test curves @121 for each batch of my products?

No, because all test equipment below 200NM, are self-built equipment; the consistency of test results from different test manufacturers itself is very poor. ICC has accumulated a lot of data here, but the assurance of the quality of the material comes from the sales of more than 500,000 pieces per year without any quality problems.

2. My lens soldering always breaks, is there something wrong with your material?

Crystal welding is a responsible technical problem, involving coefficient of thermal expansion, welding material, welding method, welding equipment, etc. and, if necessary, metallization of the lens to achieve a better pass rate. The growth of intrinsic magnesium fluoride crystals can be verified before delivery because of the high degree of automation control, and any crystal defects can be verified before delivery. Therefore, in case of crystal fracture, please consider the maturity of the process first, and consult ICC material engineer if necessary.

products and services.